Revolutionizing Engineering with Advanced Multiphysics Design

Multiscale Modeling: Bridging Nano-Scale Innovations with Macro-Scale Applications

Significant advancements have been made in modeling materials down to the nano-scale, yet translating these innovations into practical applications remains a challenge.

At DMS, we employ a top-down approach to multiscale modeling that begins at the system level. By defining boundary and initial conditions through multiphysics modeling, we integrate solutions from continuum physics with experimental data, enriching these with detailed meso-scale and micro-scale models.

This methodology ensures that our designs are not only based on theoretical models but are bolstered by empirical evidence and practical experimentation.

Materials in Extreme Environments: Pushing the Limits of Material Durability

In numerous cutting-edge technologies, the ultimate limitation is often the durability of the materials involved. This holds especially true in sectors like defense, aerospace, nuclear, and automotive, where the generation and management of energy demand materials capable of withstanding extreme heat flux. Designing for maximum longevity, our materials are evaluated based on their performance over time, with energy flux measured in kW.hr/cm². The goal is to maximize the energy flux that materials can withstand before failure, thus enhancing the economic returns of the technology. This performance is directly influenced by the severity of the heat flux, design intricacies, and manufacturing techniques, including the use of meta-materials.

Developing Innovative Materials for Future Technologies

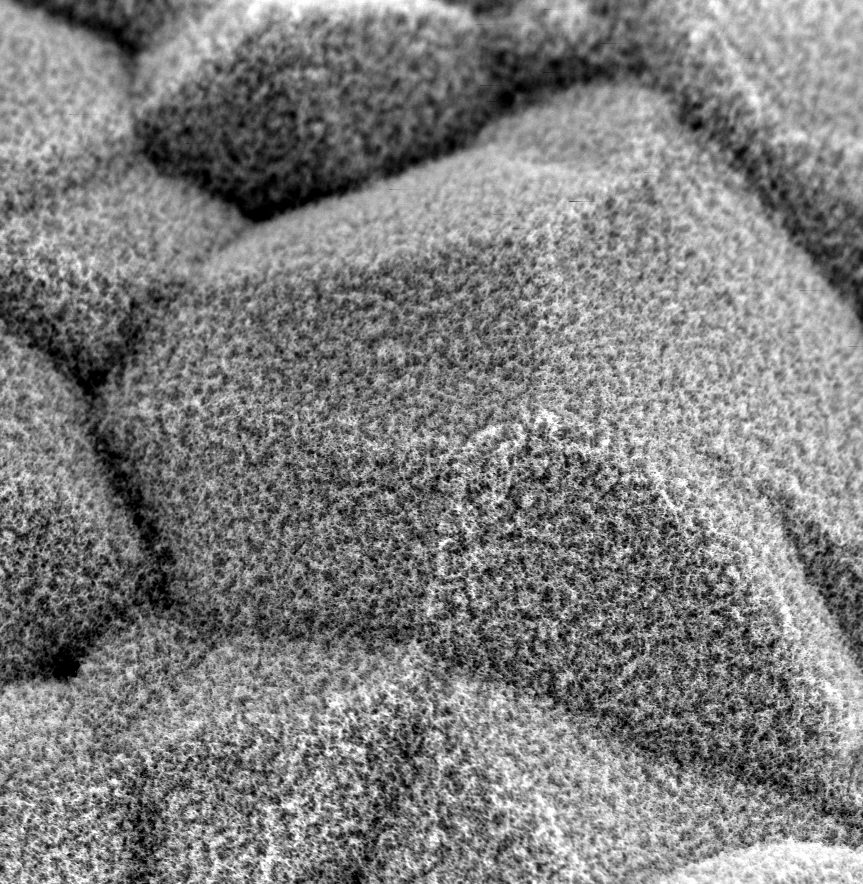

Our expertise in “Materials in Severe Environments,” combined with strategic partnerships with industry leaders like Ultramet, has led to the creation of several groundbreaking material concepts. Recent collaborations have resulted in the development of refractory metal foam structures for applications ranging from heat exchangers to plasma-resilient materials and high heat flux components. We’ve also innovated in meta-materials with unique surface textures for enhanced photon and particle interactions, as well as advanced ceramic materials designed for efficient gas release in nuclear fusion applications. These innovations are protected by our joint patents with Ultramet.

Applications in Design and Manufacturing: From Theory to Practical Implementation

DMS’s commitment to material innovation extends into the design and manufacturing stages, where we collaborate with leading industry partners such as Ultramet, Boeing, and the ADEPT group. Our developments have found applications in diverse projects, including modifications to Liquified Natural Gas containers, advanced heat exchangers, radiation-resistant space system insulation, materials for rocket engines, and insulating components for handling hot liquid metals.